- Home >

- Caring for your Pool & Spa >

- Pool & Spa Equipment > Filters

Pool Filtration System

A swimming pool must be filtered to remove insoluble particles and produce clear water.

Filtration is the physical removal of neutralised contaminants (chemicals, debris and other waste), together with the insoluble particles from the water. Clear water is desirable not only for aesthetic reasons, but for hygiene and safety.

Daily filtration cycles will vary but should be between 6 to 12 hours depending on time of year and the size and type of the system installed. It is important that at least one “turnover” is achieved - that is, as a minimum, the equivalent volume of the pool or spa is filtered each 8 hours. Filtration cycle times are best split over 2 to 3 sessions per day. You may need to increase the filtration cycle times during periods where there is a higher bather load.

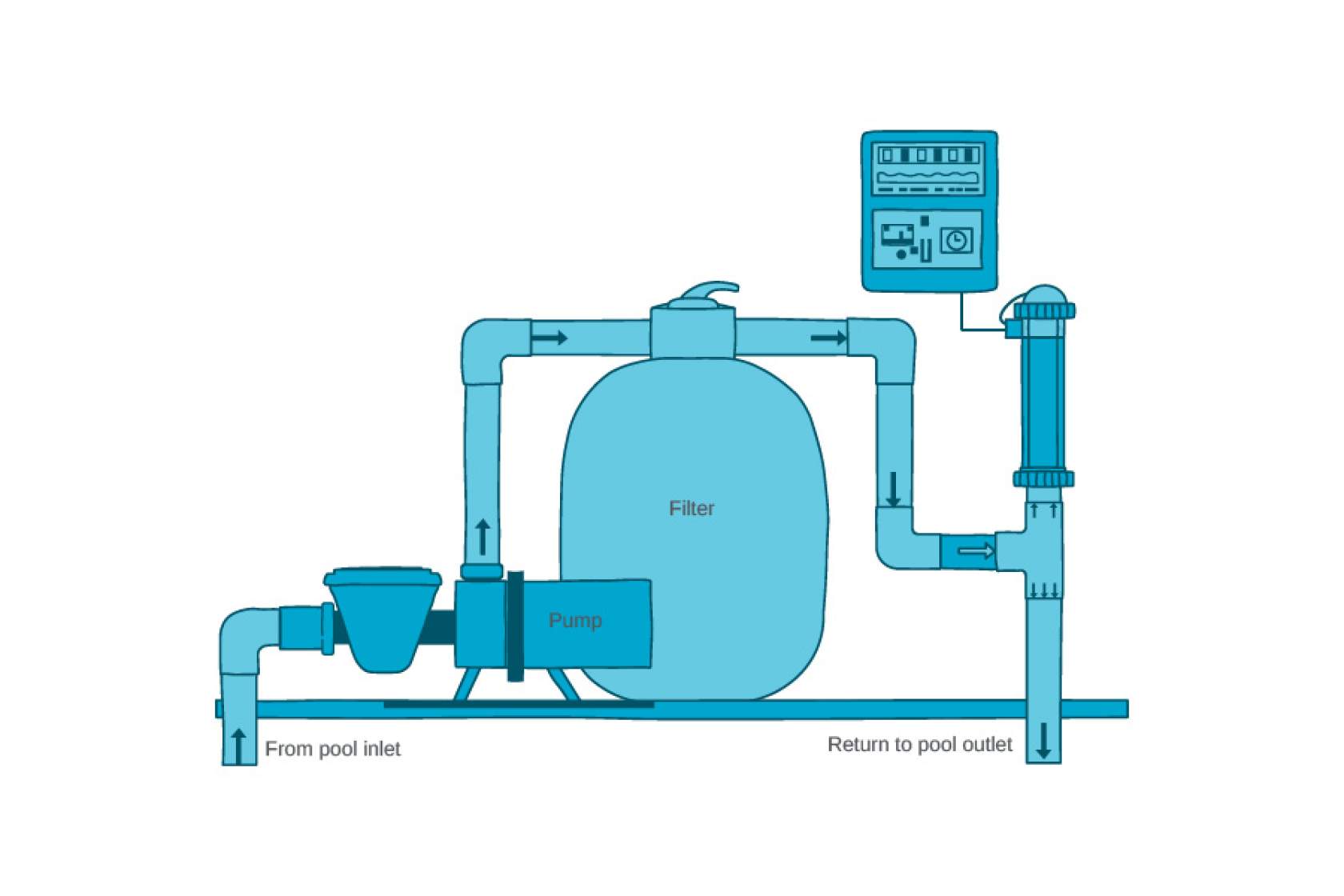

The filtration system

While filtration systems may differ regarding their type, they will all have the following basic features:

a skimmer box which allows water to enter and capture surface debris via the skimmer’s weir. A weir is the front flap located on the front of your skimmer.

an initial leaf basket in the skimmer to trap leaves and large debris, before the water is sucked through to the pump and filter.

a secondary basket situated within the pump, commonly referred to as a hair and lint

a circulating

a filter which physically removes solids from the

Pipework through which the water is circulated throughout the pool or spa.

Refer to our page on equipment setup for diagrams of the filtration system.

Types of filters

All filtration relies on removing solid matter from the water as it is pumped through the filter. The quality of filtration depends on the size of the filter media. The finer the media, the higher the purity of water obtained. There are three common types of filters:

Media – sand, glass or zeolite

Diatomaceous Earth

Cartridge

The finer the filter media, the faster the increase in pressure across the filter bed, and the more frequent the need for backwashing or filter replacement.

All of these filter types have high flow characteristics and are highly efficient. Regular cleaning is required to remove entrapped solids, reduce pressure within the filter tank and improve water flow for filtration and vacuuming, chlorination and circulation within the pool.

Most filters will have an indication on the filter’s pressure gauge when cleaning is necessary. Cleaning methods will depend upon the filter type. Media filters can be “backwashed”, which is to reverse the flow of water through the filter tank valve and flush debris to waste. Cartridge filters require removal of the cartridge so that it can be hosed down and then soaked in cartridge cleaning fluid.

It is recommended to follow the manufacturer’s cleaning directions. In addition to regular cleaning, periodic service of the filter is recommended to remove any build-up of grease and scale. This can be arranged through your local SPASA Service Technician.

Media

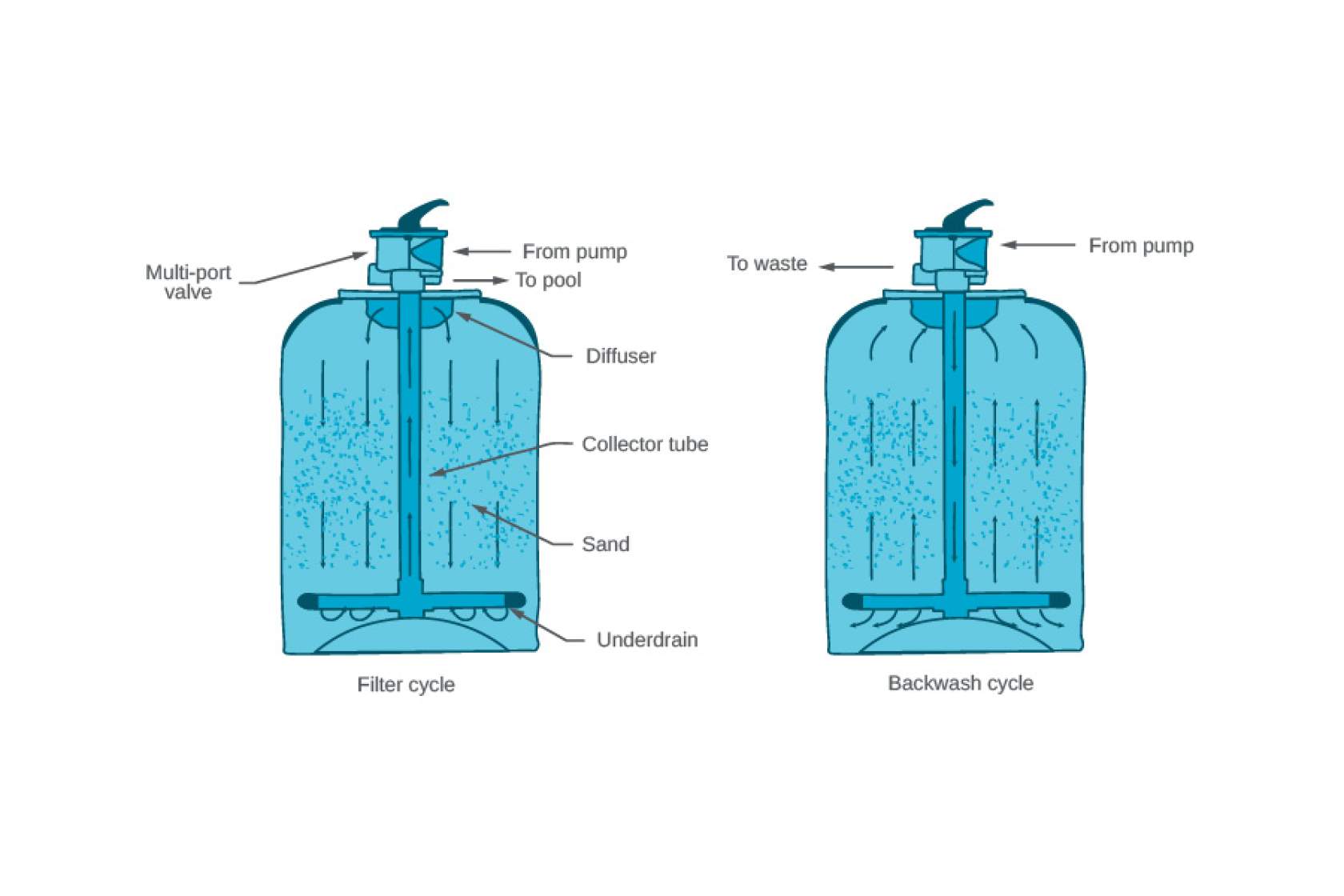

The media filter is the most common filter for both domestic and commercial pools. It requires either 16:30 grade of sand, glass media or zeolite. The media bed is 200-310mm deep, depending on the size of the tank.

Water is forced through the media bed at such a high rate that a form of mechanical flocculation takes place. The electrical charges are literally scrubbed off, allowing the dirt particles to agglomerate and form larger particles. On the next pass through the filter these larger particles are collected.

One of the benefits of the sand filter is its simplicity. When the media bed is clogged with dirt, the pressure inside will register on a gauge which indicates the need to flush it out or backwash.

This means switching off the pump and turning the valve to 'backwash'. When the pump is switched back on, the flow of water is reversed and washes up through the sand bed and removes the dirt. After backwashing the valve can be returned to the 'filter' position for normal operation. The dirty water from the filter is normally discharged into a sewer gully.

How to backwash:

Turn off the pump and turn the valve handle to backwash.

Dirty water is then directed to the waste line, to the sewer or substitute.

Watch the sight glass until the water looks clear. This process usually takes a couple of minutes.

Turn off the pump and turn the valve handle to rinse.

Turn on the pump for 1 minute then turn off.

Turn the valve handle back to filter.

Finally, turn the pump on.

Warning: You must never turn the valve handle when the pump is running. This will destroy the spider gasket inside the valve, which will lead to an expensive replacement.

Media filters will normally remove particles down to about 15 microns in size. The media in the filter will need changing approximately every five years, though this will depend on factors such as pool usage, size etc.

Diatomaceous Earth filter

Diatomaceous Earth (DE) is a powder made up from finely crushed coral-like rock. Inside the DE filter are a series of hollow plastic frames which can be square, round or tubular depending on manufacturer. Over these frames is stretched a polyester covering or pad.

Water from the pool is forced into the filter tank and through the pad. The water then runs through the center of the filter and returns to the pool.

To begin filtration, Diatomaceous Earth is mixed into a slurry and poured through the skimmer box with the pump running. It is sucked into the filter, forming a cake on the outside of the pad. As water passes through the pad, it must also pass through the cake of DE where filtering takes place. The DE cake drops from the pad when the pump is stopped, then reforms again when the pump is started.

Since the grains of DE are so fine, this type of filter has superior filtration qualities. It can remove particles down to approximately 2 microns in size. When the pressure rises it is an indication that the DE cake is clogged, and the filter needs backwashing.

This is carried out by turning off the pump and turning the valve to the backwash position. What must be remembered is that the used up DE cake is also flushed away. Therefore, it must be replenished following every backwash.

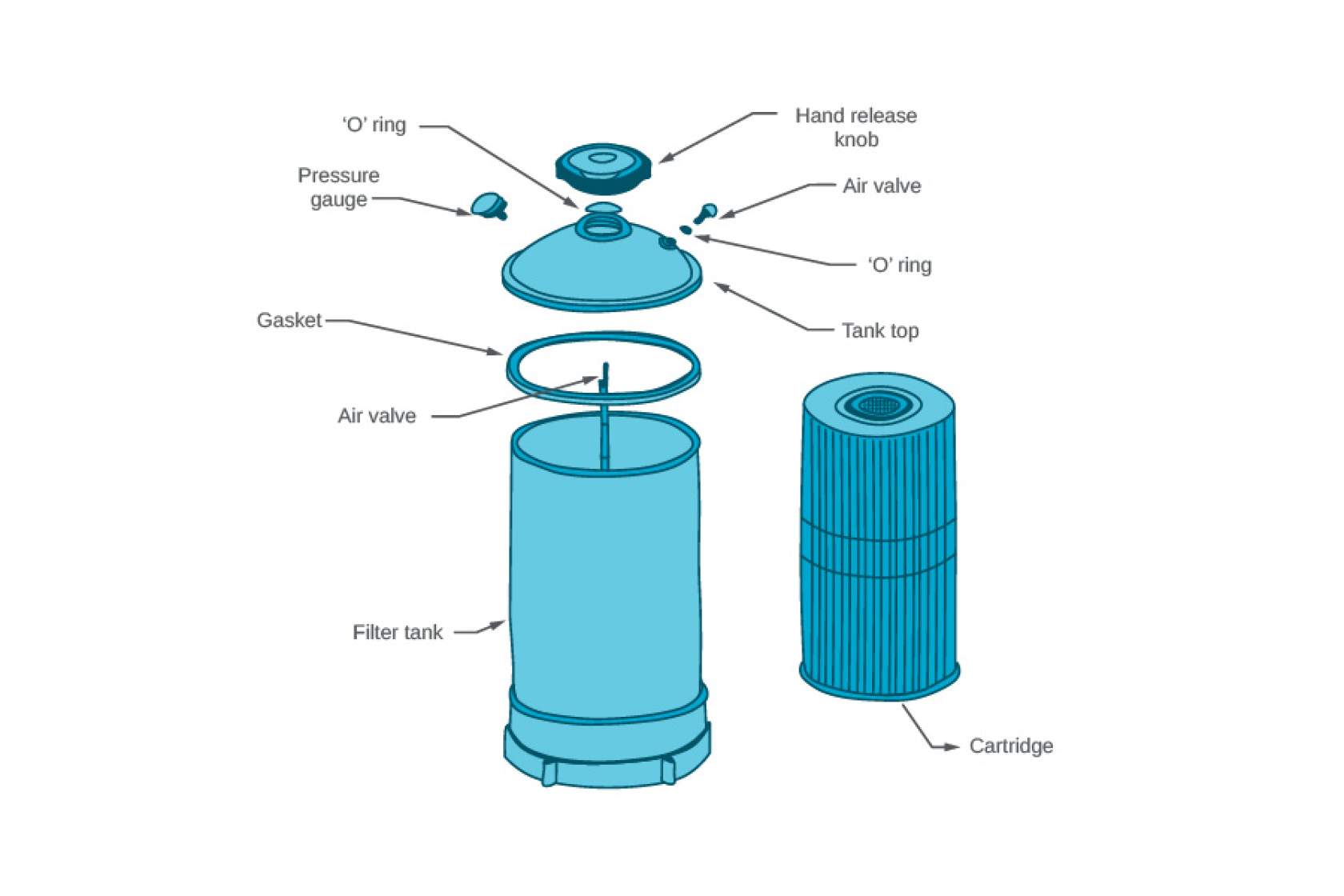

Cartridge filter

The cartridge filter incorporates the benefits of both media and Diatomaceous Earth. The filtering medium is a concertina shaped cartridge providing a large filter surface within a relatively small housing. This large filter area means the filter cycle, or period between cleaning, is increased. It removes particles down to approximately 10 microns in size.

Unlike other filters, there is no provision for backwashing. When the cartridge is clogged, it must be removed for cleaning. Cartridge filters require removal of the cartridge so that it can be hosed down and then soaked in cartridge cleaning fluid.

There is a gauge on top of the filter which indicates when to clean the filter. Usually, the cleaning process happens monthly. Cartridge filters include an air release valve which you should activate after every clean.

One of the advantages of the cartridge filter is that the method of cleaning makes it ideal for use in un-sewered areas or where disposal of waste is a problem. Always refer to the manufacturer for installation and maintenance of filters. Cartridge filter elements usually last three to five years, depending on quality and use.

Discharging water

Discharging wastewater during a backwash cycle or hosing down a cartridge filter is an important part of filter maintenance; however, it is important to note that wastewater being discharged must not be disposed of via any storm water system or allowed to simply run off onto adjoining land. You may need to make enquiries with your local council or water provider to see what is permissible in your state or territory.